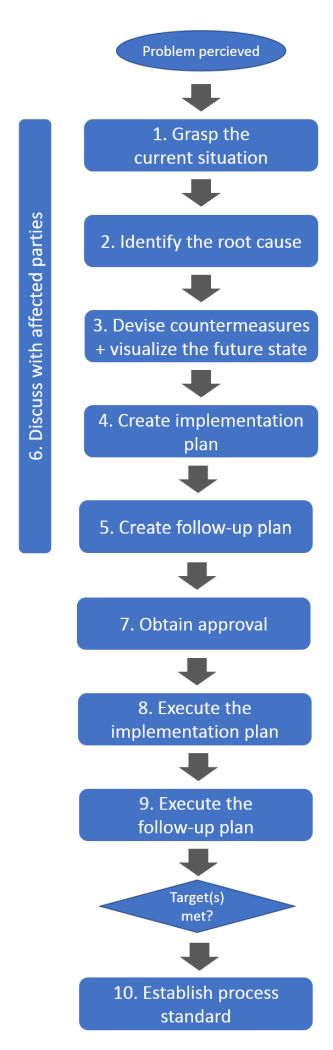

Art Smalley en Durward K. Sobek II beschrijven in hun boek Understanding A3 Thinking de stappen die nodig zijn voor 'praktische probleemoplossing' (practical problem solving):

![]()

We have distilled a general process for approaching problems that occur during the course of work, based on our observations and research on Toyota. The same basic process is followed for proposals to take advantage of opportunities. The process appears serial, but in fact it tends to be iterative in nature, as steps are repeated as needed to remedy any shortcomings or adress concerns that arise at a later stage. ... The first seven steps represent the Plan step of the PDCA cycle. After proprosal, the team immediately enters the Do step, followed by the Check step. If results are satisfactory, the new change becomes standard operating procedure, completing the Act step of PDCA; otherwise, the whole process begins anew, as indicated by the dashed loop-back arrow.

(1) Grasping the current situation

The problem-solving step that perhaps most distinguishes Toyota from any other company is the first step of the problem-solving cycle: grasping the current situation. What Toyota means by this phrase is gaining a thorough understanding of the process or system that gave rise to the problem, in the context where the problem occurred. The context is critical because, frequently, the key to resolving a problem is in a detail that no one has yet noticed (for if anyone had, the problem would have been prevented).

(...)

In that vein, then, the problem-solver must clarify the problem. The most common first step at Toyota is to travel physically to the actual location (the genba) where the problem occurred, and observe the situation firsthand. It also means talking with the people involved to find out exactly where the problem occured, when, and under what conditions. Clarifying the problem further involves finding out why the problem is a problem; that is, what should be happening that is not, or what is not happening what should be?

(...)

Going to the genba to observe and to understand is an effective way to verify and update a personal's mental image of how the system works, making it more accurate to reality.

(...)

Once the problem-solver feels he or she has a sufficient grasp of the situation, he or she should draw a picture or diagram to illustrate the current situation, process, or system and the problem(s) observed; or, if the situation is not amenable to pictorial representation, describe it in narrative form. The problem-solver can then share this documentation with others involved in or affected by the problem to confirm the accuracy of the picture and/or to add or modify to incorporate new information.

(2) Identifying the root cause

At the point of cause, it is usually fairly straightforwar to identify the direct cause of the problem. What is the immediate thing that is happening (or not happening) that is creating the problem? This should be confirmed through additional observation or experimentation, as it would be highly unproductive to implement a countermeasure that does not address the problem.

However the most obvious cause is rarerely the root cause. So the problem-solver continues the investigation until a root cause is found, one that if taken care of, would eliminate all future occurences of the problem. A common method for investigating root causes is the five why approach. The problem-oslver asks, "Why is this problem occurring?" Upon answering it, he or she will have identified a cause to the observed effect. The problem-solver then asks the question again, this time turning the cause into an effect, to identify a deeper cause. The problem-solver continiues this inquiry until recurrence can be prevented by addressing that cause. When completed, the problem-solver has a clear and coherent cause-effect chain that demonstrates an in-depth understanding of the problem in context, noting how the root cause is linked to the observed phenomenon. The cause-effect chain should be shared with others to verify that it is probable and reasonable.

In other cases, however, the root cause cannot be deduced from the five-whys technique, and structured tests or experiments are used to eliminate possible causes.

(...)

(3) Devising countermeasures and visualizing the future state

Once the root cause(s) have been identified, the problem-solver can then begin to brainstorm specific changes to the current system that address the root cause(s). Toyota calls these specific changes countermeasures. Often, the countermeasures will be suggested during the course of understanding the current situation and investigating the root cause. The countermeasures should be designed to prevent recurrence of the problem.

(...)

(4) Creating an implementation plan

In some organizations, great ideas bubble to the surface only to languish because no clear path to implementation has been laid out. Or great ideas fail to realize their potential because the implemenation, rather than the idea, is flawed. So creating an implementation plan is part of a rigourous problem-solving process.

(...)

(5) Creating a follow-up plan

A rigourous problem-solving methodology should include a plan for how the actual results will be verified against predicted outcomes. Similar to the implementation plan, the precise activivities are made explicit along with the person responsible for making such each action happens, and dates for when those activities will occur. Allthough this sounds simple, it is most often not conducted at all.

(...)

(6) Discuss with affected parties

Discussing one's learnings and ideas with those affected by the change occurs throughout the Plan phase. Even with those continuous discussions, it is fruitful to approach those individuals again with the whole picture, from diagram of the current situation and diagnosis of root cause through implementation and follow-up plans, to ensure as much alignment as possible.

(...)

(7) Obtaining approval

At Toyota any change must receive approval before it is allowed. At first glance, such a rul may seem overly bureaucratic, but i actually plays a critical role in the success of the management system once you understand what the approval step represents. First, and perhaps most importantly, the approval step is an explicit mentoring opportunity. Usually the approval must be obtained from one's manager (or manager's manager). This gives the managar the opportunity to mentor the problem-solver, enhance his or her investigative and deductive reasoning skills, help build communication and social networking abilities, and challenge the rigor of the A3 approach. A3 reports actually make mentoring an easier and more accesible task because they make the report author's thought processes visible. Once thes thought processes are visible, the mentor can encourage the strong aspects and attempts to shore up the weak aspects.

Second, the approval check ensures the rigor and objectivity of the process, and the depth of the understanding obtained. Did the investigator visit the genba? Does the root cause make sense? Do the countermeasures adress root causes? Is the implementation plan realistic? Is the follow-up plan substantive? Did the problem-solver talk with the right people? Are all the right people agreeable to the proposed change?

(...)

(8) & (9) Executing the implementation and follow-up plans

Upon approval, the implementation plan is executed. To Toyota people, it is critical that the implementation plan be executed according to plan, at least to the extent possible. This is important to separate the effects of the countermeasures and implementation, and to incrementally improve planning skills.

Following implementation, or at times concurrent with implementation, the problem-solving teams execute the follow-up plan to determine whether the change produced the predicted effects. Pending these results, two courses of action are possible. If the results are satisfactory, the new change is established as the standard process and result are dissemnated to other groups that may have similar situations. The perspective here is that the implementation is (to the extent possible) an experiment. If it does not work out, then you return to the old system until you find something better. If the results are not satisfactory, the team engages in an abbreviated problem-solving process to discover why the results were not satisfactory and to take corrective action.

Bron: Understanding A3 Thinking, Durward K. Sobek & Art Smalley