Art Smalley en Durward K. Sobek beschrijven in hun boek Understanding A3 Thinking - A Critical Component of Toyota's Pdca Management System hoe de PDCA-cyclus het hart vormt van de 'Toyota Way':

![]()

PDCA: Heart of the Toyota Way

... Why do we not see more companies emulating Toyota's success?

While there may be many explanations, perhaps the most crucial one is that most of us do not understand - or if we understand, do not appreciate - what is at the heart of the Toyota business, management, and manufacturing approach. We tend to see the intricate set of tools as the system. But although they are important to the system as currently enacted, they are at the surface, not the heart. In fact, Taiichi Ohno, the father of the modern Toyota production system, said that the tools are just countermeasures to business problems that Toyota has faced and that they will be used only until better countermeausers are found. In other words, the interconnected web of tools and practices we know as lean manufacturing is the outcome of a deeper set of processes. These deeper processes, we argue, are at the heart of Toyota's system.

So how did the Toyota system emerge? In simple terms, it emerged as Toyota's people saw problems or opportunities, "solved" the problem aggresively and systematically to find a better way to do things, and then rigorously verified that the better way was indeed better. If the remedy did indeed improve the system, the new way became the standard way to do the work; if not, problem solving and verification continu until the problem is satisfactorily addressed.

The roots of this process are grounded in the scientific method of inquiry.

(...)

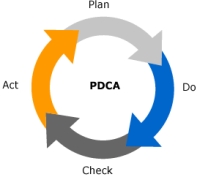

The problem-solving approaches in use at Toyota today are also deeply influence by a high-level methodology initially developed by Walter Shewhart of Bell Labs in the 1930s, and later adopted by W. Edwards Deming who became the biggest prselytizer. The methodology is the Plan-Do-Check-Act (PDCA) cycle, also called the Demming Cycle.

(...)

The PDCA cycle begins with the Plan step, in which the problem-solver thoroughly studies a problem or opportunity to understand it from as many viewpoints as possible, analyzes it (quantitatively, if possible) to find the root causes, develops one or more ideas to remedy the problem or seize the opportunity, and devises a plan for implementation. In the Do step, the plan is put into action as immediately as is possible and prudent. The Check step involves measuring the effect of implementatoin and comparing them to the target or prediction. Act refers to establishing the new process, solution or system as the standard if the results are satisfactory, or taking remedial action if they are not.

The PDCA cycle simply follows the steps of the scientific method: Plan is developing a hypothesis and experimental design; Do is conducting the experiment; Check is collecting measurements; and Act is interpreting the results and taking appropriate action.