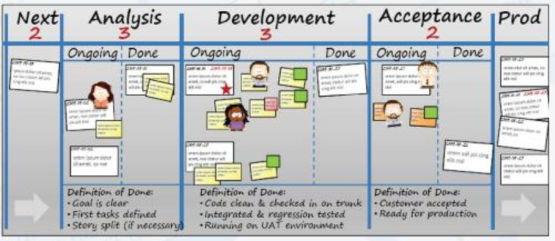

In het boek Kanban and Scrum - making the most of both beschrijven Henrik Kniberg en Mattias Skarin het Lean-instrument van de Kanban:

![]()

Kanban is based on a very simple idea. Work in Progress (WIP) should be limited and something new should be started only when an existing piece of work is delivered or pulled by a downstream functioe. The kanban (or signal card) implies that a visual signal is produced to indicate that new work can be pulled because current work does not equal the agreed limit.

(...)

The principle of Kanban is that you start with whatever you are doing now. You understand your current process by mapping the value stream and then you agree to WIP limits for each stage in that process. You then start to flow work through the system by pulling it when kanban signals are generated.

(...)

Because WIP is limited in a Kanban system, anything that becomes blocked for any reason tends to clog up the system. If enough work items become blocked the whole process grinds to a halt. This has the effect of focusing the whole team and the wider organization on solving the problem, unblocking the item and restoring flow.

Kanban uses a visual control mechanism to track work as it flows through the various stages of the value stream. Typically, a whiteboard with sticky notes, or and electronic card wall system is used.

(...)

Kanban exposes bottlenecks, queues, variability and waste - all of which are things which impact the performance of the organization in terms of the quantity of valuable work deliverd and the cycle time required to deliver it. Kanban provides team members and external stakeholders with visibility into the effect of theri actions (or inactions.) As such, early case studies are showing that Kanban changes behavior and encourages greater collaboration within the workplace. The visibility into and impact on bottlenecks, waste and variability also encourages discussion about improvements, and teams quickly start implementing improvements to their process.

(...)

Through the nature of the pull system, Kanban also encourages delayed commitment on both prioritization of new work and delivery of existing work. ... This improves agility by managing expectations, shortening cycle times from commitment to delivery and eliminating rework since the change that priorities will change is minimized.

One final word on Kanban is that the effect of limiting WIP provides predictability of cycle time and makes deliverables more reliable. The "stop the line" approach to impediments and bugs also appears to encourage very high levels of quality and a rapid form of rework.

(...)

Kanban in a nutshell

(1) Visualize the workflow

- Split the work into pieces, write each item on a card and put on the wall

- Use named columns to illustrate where each item is in the workflow

(2) Limit Work in Progress (WIP)

Assign explicit limits to how many items may be in progress at earch workflow state.

(3) Measure the lead time (average time to complete one item, sometimes called 'cycle time'), optimizing the process to make lead time as small and predictable as possible.

(...)

Summaryof Scrum vs. Kanban

Similarities

· Both are Lean and Agile

· Both use pull scheduling

· Both limit WIP

· Both use transparency to drive process improvement

· Both focus on delivering releasable software early and often

· Both are based on self-organizing teams

· Both require breaking the work into pieces

· In both, release plan is continuously optimized based on empirical data (velocity / lead time)

Differences

| Scrum | Kanban |

| Timeboxed iterations prescribed. | Timeboxed iterations optional. Can have separate cadences for planning, release, and process improvement. Can be event-driven instead of timeboxed. |

| Team commits to a specific amount of work for this iteration. | Commitment optional. |

| Uses Velocity as default metric for planning and process improvement. | Uses Lead time as default metric for planning and process improvement. |

| Cross-functional teams prescribed. | Cross-functional teams optional. Specialist teams allowed. |

Items must be broken down so they can be completed within 1 sprint. |

No particular item size is prescribed. |

| Burndown chart prescribed. | No particular type of diagram is prescribed. |

WIP limited indirectly (per sprint) |

WIP limited directly (per workflow state) |

| Estimation prescribed |

Estimation optional |

| Cannot add items to ongoing iteration. | Can add new items whenever capacity is available |

| A sprint backlog is owned by one specific team | A kanban board may be shared by multiple teams or individuals |

Prescribes 3 roles (PO/SM/Team) |

Doesn’t prescribe any roles |

A Scrum board is reset between each sprint |

A kanban board is persistent |

Prescribes a prioritized product backlog |

Prioritization is optional. |

Bron: Kanban and Scrum - making the most of both, Henrik Kniberg & Mattias Skarin