![]()

Value stream mapping is the missing lik in business management. (...) We view value stream thinking as a fundamental mindset for business success. Without it, organizations fail to develop customer-centric processes and fail to organize in a way that best serves the very reason they exist.

Value stream mapping is a practical and highly effective way to learn and see and resolve disconnects, redundancies, and gaps in how the work gets done.

Value stream mapping presented a holistic and visual way to deeply understand how work gets done and to design and improve future state.

(...)

What Is Value Stream Mapping?

The roots of value stream mapping can be traced to a visual mapping technique used at the Toyota Motor Corporation known as "material and information flows." As the West grew intrigued with Toyota's consistent track record and began studying how Toyota's approach differed from its own, we learned that Toyota's focus on understanding the material and information flow across the organization emerged as a significant contributor to its ability to perform at consistently high levels.

(...)

Mike Rother and John Shook studied Toyota's "material and information flow mapping" and recast the method as "value stream mapping" in the landmark book Learning to See (1999). The result of Rother's studies and Shook's 10 years of experience in a leadership role at Toyota, Learning to See provided us with the first tangible method for "seeing" the value streams that Womack et. al defined. After using value stream mapping for over 10 years to transform operations in nearly every industry, we believe it's the most powerful, yet under-utilized improvement "tool" we've seen to date. But the power behind value stream mapping lies in a little understood reality: it's far more than just a tool.

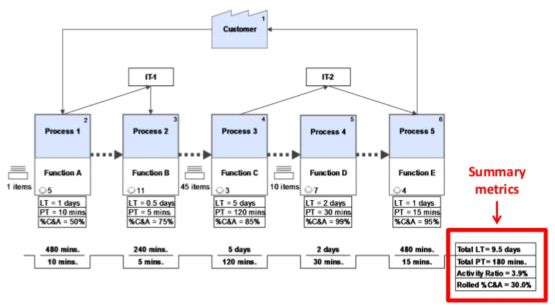

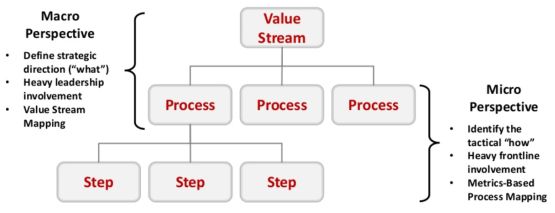

Value stream maps offer a holistic view of how work flows through entire systems, and they differ from process maps in several significant ways. First, value stream maps provide an effective means to establish a strategic direction for making improvement. The inclination to jump into the weeds and design micro-level improvements before the entire work system—the macro picture—is fully understood, is a key contributor to suboptimization. As shown [below], work has various degrees of granularity. Value stream mapping, the macro perspective, provides the means for leadership to define strategic improvements to the work flow, whereas process-level mapping enables the people who do the work to design tactical improvements.

(...)

Second, value stream maps provide a highly visual, full-cycle view—a storyboard—of how work progresses from a request of some sort to fulfilling that request. This cycle can be described as request to receipt, order to delivery, ring to ring (phone call to cash register), cradle to grave, or quote to cash. A cyclical view places the customer (who is typically both the requester and recipient) in a central position, which provides a powerful means to view an entire work system as it relates to delivering customer value.

Third, the process of value stream mapping deepens organizational understanding about the work systems that deliver value and support the delivery of value to customers, which aids in better decision making and work design. By distilling complex systems into simpler and higher-level components that can be understood by everyone from senior leaders to the front lines, organizations create common ground from which to make decisions. In addition, the mental shaping that's needed to succinctly define complex work systems is a boon when redesigning work to deliver greater value, faster, at lower cost, and in safer and more fulfilling work environments. There's a logistics advantage as well: value stream mapping enables a team to fully understand how work flows through a complex system in a matter of days, whereas detailed process mapping (which serves a different purpose) can take weeks or months and is too detailed to help in making effective strategic decisions.

Fourth, the quantitative nature of value stream maps provides the foundation for data-driven, strategic decision making. Measuring overall value stream performance and identifying the barriers and process breakdowns as the work flows through the value stream is a powerful way to drive continuous improvement so that an organization is able to better meet the needs of both its customers and its internal operation.

Last, value stream maps reflect work flow as a customer experiences it versus the internal focus of typical process-level maps. Many organizations are structured as a series of function-based silos that bear little relationship to the customer fulfillment cycle. [Value stream maps] force an organization to think holistically in terms of cross-functional work systems and product families. While this type of thinking can pose challenges during the future state design phase of mapping, it's exactly the type of challenge progressive organizations must embrace. Value stream mapping forces an organization's hand to either make the difficult structural changes that are more in line with the cross-functional reality within which they exist, or continue to deny reality, stick with outdated structures, and continue to perform accordingly.

Bron: Value Stream Mapping - How to Visualize Work and Align Leadership for Organizational Transformation, Karen Martin & Mike Osterling